Description

THE ORIGINATOR, NOT THE IMITATOR!

MSE Shifters are engineered ESPECIALLY for use with Volkswagen Transaxles. Other shifters are not specifically made for Volkswagen Transaxles and may subject you to shifting problems.

-The MSE Shifting System has been race proven since 1995.

-It is used internationally to provide the fast, positive shifting that you need to be a winner.

-No more missed shifts, stuck in gear, hit reverse, and all of those other shifting problems you have had.

-MSE WILL CURE YOUR SHIFTING PROBLEM!

-YOU’VE TRIED THE REST, NOW USE THE BEST!

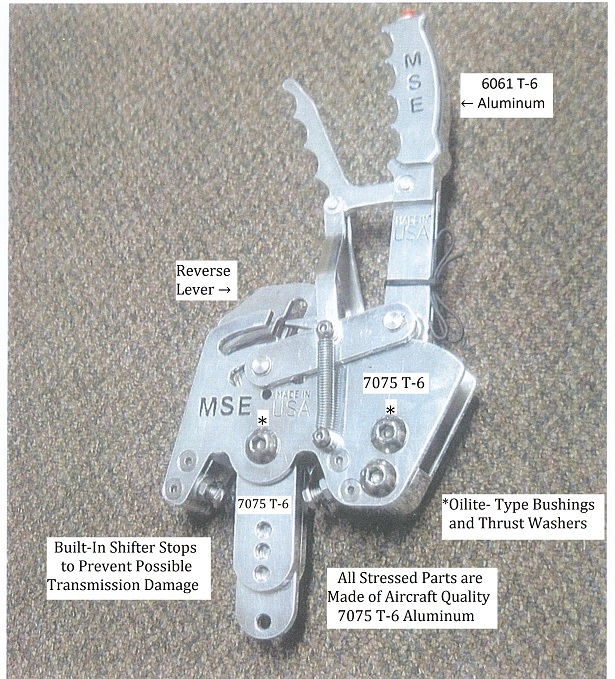

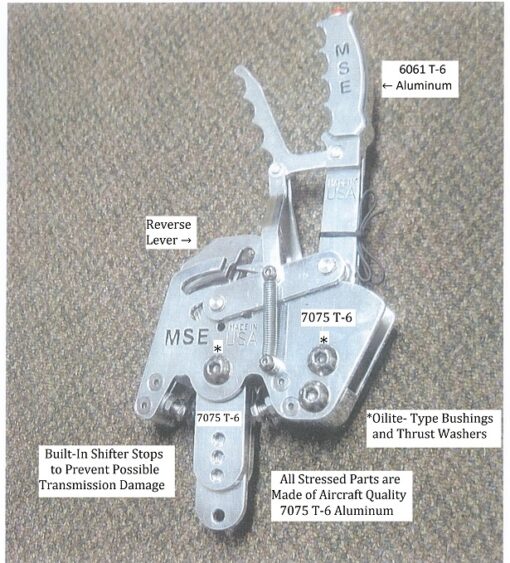

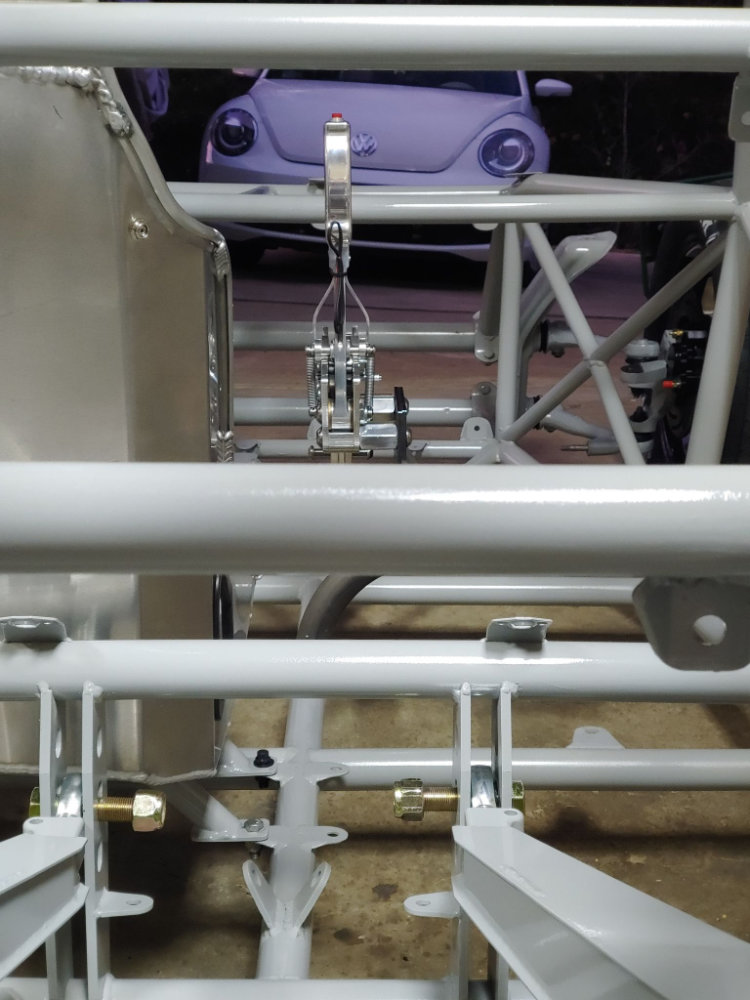

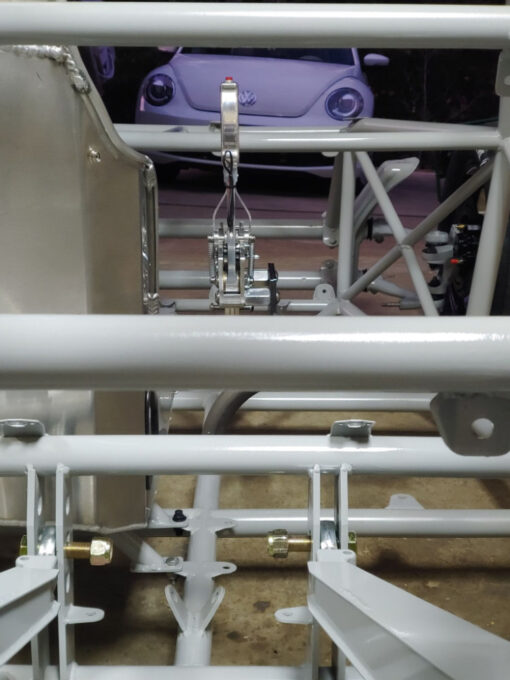

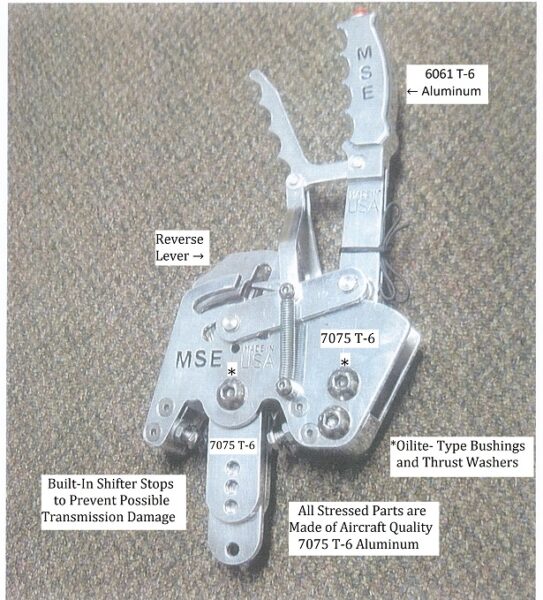

Exclusive Features of MSE Shifters Our In-Line Pistol Grip Shifter is used predominantly in drag racing; however, it can be used in other applications such as street, off road, etc. The shifter function is rather simple: a separate rod controls the 1st & 2nd gear, the 3rd & 4th gear, and reverse. Coupled with the RLR/MSE Posi-Shift Housing this system eliminates the troublesome VW “Hockey” stick with three separate shift levers. Not only will your shifts be more precise, you will be able to shift more quickly, the reason being that the V-Gate shifter eliminates the “H” pattern of a normal shifter. With simple “back, forward, and back again” shift motions, your e.t.s will drop with less shifting effort. This unique system is offered as a complete package with shifter, rods, and housing, or as separate components. Please specify Type1 or Type2 Posi-Shift Housing. parts are 6061 T-6 and/or stainless steel. All pivoting parts use SAE-841 Oil Impregnated bronze Oilite™ bushings and thrust washers which are self-lubricating and do not require lubrication. Oilite™ is used rather than aluminum to aluminum which is a very poor bearing surface and can lead to galling. Any wear would be on the bushings which are inexpensive and replaceable. All aluminum parts are polished and treated to protect the surfaces and preserve the original appearance. You will find this to be the strongest, most durable and best shifting light-weight shifter available. While it is not possible to obtain the strength and durability of our 4130 Chrome-Moly shifter parts, this shifter is designed to give you years of trouble-free service. The new MSE shifter now has an integral reverse. Reverse is selected with the same squeeze lever as forward gears. A reverse block is used to avoid accidentally engaging reverse. All shifters are equipped with a thumb operated switch to operate line lock or the component of your choice.

Reviews

There are no reviews yet.